Loading component...

At a glance

- Rare earth elements are essential components used in LCDs, lasers, rechargeable batteries and fibre optic cables, among others.

- Rare earths are not particularly rare, but mining, extracting and recycling them can be complex and expensive.

- For accountants, the challenge lies with governance and the supply chain of rare earths, including establishing the provenance of a supply.

In the Geoscience Australia laboratory in Canberra sits a very small magnet that seems, at first, to be utterly unremarkable. It is the size of a 20 cent piece and looks like a magnet that a child might play with, sticking to the sides of filing cabinets or snapping onto fridges.

A child shouldn’t play with this one. If they were to trap their finger between this tiny but deceptively powerful magnet and a steel surface, they would end up in hospital, their finger painfully crushed.

That power comes from the fact that it’s a rare earth magnet, so named because it contains neodymium, one of 15 lanthanide elements (plus their close “cousins” yttrium and scandium) on the periodic table that make up the group known as rare earth elements. Rare earths have been important components in modern electronics for a long time, but are now experiencing steep growth in demand, as technology creates greater need for them.

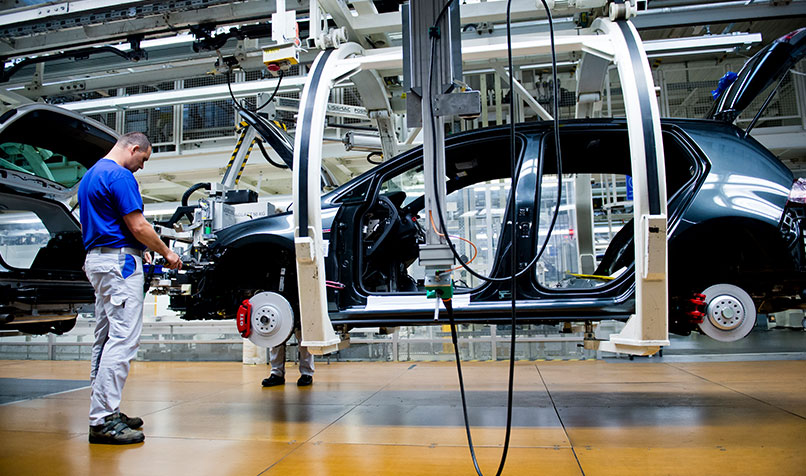

These elements are essential ingredients in everything from LCD displays to lasers, from rechargeable batteries to magnets required for electric car motors, and from fibre optic cables to catalysts used in oil refining. As the world’s appetite for technology increases, as we move towards electric vehicles and as every individual owns several handheld digital devices, the need for rare earths increases.

Supply and demand

However, the industry has its problems. Geopolitical issues, for example, sometimes make an already opaque market even more difficult to navigate. A decade ago, China decided to cut its exports of rare earths by about 40 per cent. At the time, China produced the overwhelming majority of the world’s rare earths.

“That export restriction was partly due to their desire to dominate the industry,” says Richard Schodde, minerals economist and managing director of MinEx Consulting. “It was also driven by a desire to use the rare earths as a value-add item. Rather than sell the rare earths, why not make the magnets? And if they’re making magnets, why not make the motors and the cars that use those magnets? This was a critical ingredient for turning China into a high-tech economy.”

The result was an explosion in the price of rare earths, a tenfold increase on average across the various elements, Schodde says.

Other producers began filling the void, so when China eventually lifted restrictions, its market share had dropped dramatically, says Allison Britt, senior commodity specialist and activity leader, mineral resources and advice at Geoscience Australia.

“China has dominated rare earths production since the Mountain Pass Rare Earth Mine in the US closed in 2002,” Britt says, “but when China restricted exports, it made a few people in various countries nervous. Some saw it as an opportunity, and in Australia we saw Lynas popping up with its Mt Weld project, as well as Nolan’s Bore near Alice Springs, the Dubbo Project in central New South Wales and the Browns Range Project in Western Australia.

“These projects are coming online as a response to perceived supply restrictions from China, which now supplies only about 60 per cent of the world’s rare earths demand, down from about 95 per cent.”

What's with the "rare"?

Actually, rare earths are not particularly rare. According to mining.com, the least abundant rare earth elements – thulium and lutetium – are still almost 200 times more common than gold. Plus, they are often required only in small amounts, leading to them being referred to by some as the vitamins of the minerals industry.

The group was first referred to as rare earths because chemists in the 1800s had such a difficult time isolating each element. This points to one of the major problems with the extraction and processing of rare earths – it can be difficult and dirty, even with today’s technology.

"The group was first referred to as rare earths because chemists in the 1800s had such a difficult time isolating each element.”

It’s not just a matter of digging up the minerals, explains Britt. Some can be radioactive and in other cases, only 1 per cent might be rare earth minerals. Mined material must be crushed into a very fine powder to begin the process that allows the minerals to be liberated.

“They’ll then use different technologies to isolate the specific elements,” Britt says. “They might put the crushed ore into flotation tanks, so some of the materials will sink and some will float. They might have to bubble air through it. Then they might do some baking and bleaching.

“Some miners send rare earth carbonate to Chinese companies for splitting into the different elements. That usually involves a process of solvent extraction using highly toxic acids, and they can put the materials through these solvent cycles up to 100 times, just to separate all of the rare earths from each other.”

Governance issues

The complex and sometimes dangerous processing of rare earth materials is one challenge. Another is the non-transparent nature of the industry.

“It’s not about digging a big hole, pulling out a heap of coal and sticking it on a boat,” says John Purcell, FCPA CPA Australia’s policy adviser, environmental, social and governance.

“Instead you have relatively small physical quantities of highly valuable material that pass through a number of hands. The challenge from an accounting and a governance perspective is often centred on the capacity to trace the provenance of the materials.”

Where did the product originate? Whose hands did it have to pass through? What was their take? Purcell points out that many of these challenges are typical accounting types of issues. Understanding the rare earths industry is about understanding a transaction as it moves through a number of parties within a supply chain.

A diligent accountant, he says, must achieve an appropriate level of confidence that the transactions are correctly accounted for, and that risk points within the supply chain do not give rise to adverse exposure, in terms of “modern slavery, bribery of foreign officials, undue payments, money laundering and even to hide terrorism financing”.

“A lot of work is developing around blockchain technology to understand and manage provenance, both from the due diligence perspective and from a good accounting perspective in terms of reducing risk. There is an important role for accounting because the governance risks are significant.

“Important also are financial accounting considerations requiring diligent assessment and application of relevant accounting standards, most particularly AASB 6 Exploration for and Evaluation of Mineral Resources, and input into significant market-related disclosures such as the Australasian Code for Reporting Exploration Results, Mineral Resources and Ore Reserves (the JORC Code).”

Cleaning up the rare earths act

A dirty and difficult production process deserves a clean and green recycling solution. For too many years the process to recycle rare earths has been just as toxic as their original extraction and refining.

However, researchers at Australia’s Deakin University recently announced a breakthrough in the recycling process.

“We have a device or product that contains these materials. How do we recover the rare earth elements from that device?” asks Dr Cristina Pozo-Gonzalo, a senior research fellow in Deakin University’s Institute for Frontier Materials.

“Typically, only a very small percentage of these materials is recovered from end-of-life products through recycling – only 3 to 7 per cent. The efficiency is not very good. Some of the techniques being used at the moment require very high temperatures, up to 800°C. That requires a great deal of energy and it is expensive.”

"The challenge from an accounting and governance perspective is often centred on the capacity to trace the provenance of the materials."

Pozo-Gonzalo’s team is at proof-of-concept stage with a process that can extract rare earths at just 75°C, decreasing energy used and waste generated and without using aggressive solvents, such as sulfuric acid.

“After separating the metals from their end-of-life product, our team uses advanced electrolytes known as ionic liquids to recover the rare earth materials from the resulting solution using a process of electrodeposition – when you use a low electric current to cause metals to reform and deposit on a desired surface,” she says.

“This new method for recovering rare earth metals has great potential and minimises the generation of toxic and harmful waste. We are also aiming for a method that can easily be implemented widely across the world.”

The economic argument

Rare earths are complex elements. Some of them are highly valuable in the market; others are not. Some are in increasing demand; some are on the way out. Pricing can vary quickly and dramatically, and it can sometimes be difficult to understand why.

“There are only a limited number of companies that buy rare earths,” Schodde says. “They may buy under a long-term contract or may have severe pricing penalties associated with impurities. The buyers might also financially support certain exploration companies, to get them into production, so there is uncertainty in pricing.

This makes it difficult for companies to raise the necessary finance to build their project.”

Adding to the complexity of the market is the fact that it is relatively small, so the major players such as BHP and Rio Tinto tend to stay away. Junior and niche companies, typically private businesses, make up the bulk of the industry.

Collective global annual demand for rare earths, Schodde says, is roughly 170,000 tons and is growing at 8 per cent. Basket price is about US$25,000 per ton, meaning the global market value is in the order of US$4 billion.

“A new entry to the market might only capture 10 per cent market share, or US$400 million to US$800 million per year in revenue,” he says. “Many of the junior companies probably have a market cap of US$50 million to US$100 million, but the project they need to build will cost many times that amount. They don’t have the capital to make it happen, so they have to raise additional funds. This all adds to the risk, uncertainty and delays.”

From where is the extra demand for rare earths coming? One of the biggest players is the electric car industry. One electric car contains about 16kg of rare earths and, according to forecasters, half the new cars built in the world will be electric within 10 to 20 years, Schodde says.

Despite their name, experts say the world is not likely to run out of rare earths anytime soon. Schodde keeps a database of about 58,000 significant mineral deposits around the globe.

This includes 270 rare earth deposits, plus several hundred other deposits containing minor amounts of these metals. About 30 of these are currently being mined. Even with strong growth at the right price, there are sufficient known resources available to meet future demand for several decades.

There is plenty more in the ground, if necessary.